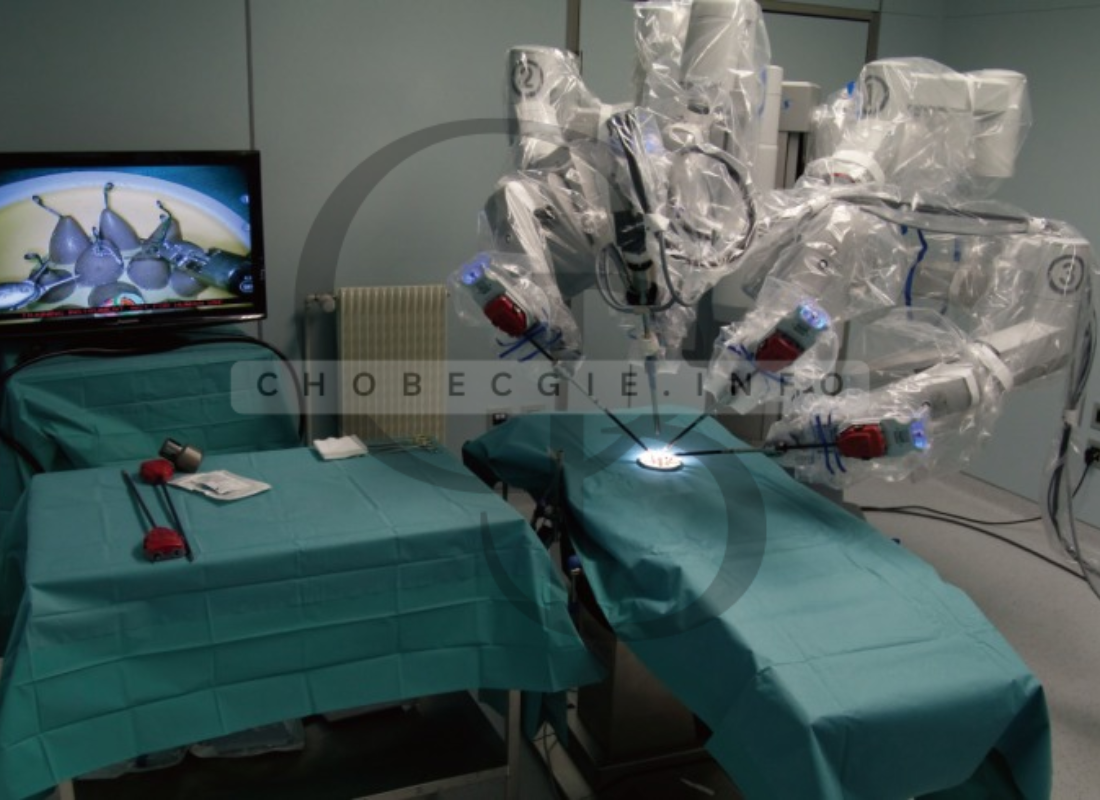

The Da Vinci Surgical System has transformed the field of minimally invasive surgery, offering unparalleled precision, control, and efficiency. Installing this advanced robotic system is a critical process that requires meticulous planning, collaboration, and technical expertise. A successful installation ensures that the system operates at its full potential, enabling healthcare providers to deliver the highest standard of care. This article explores the essential steps, considerations, and benefits of a seamless Da Vinci system installation, highlighting its impact on revolutionary surgical practices.

Why Proper Installation of the Da Vinci System Matters

A well-executed installation is crucial for the optimal performance of the Da Vinci system. Here’s why:

1. Maximizing Efficiency

Proper setup ensures the system functions smoothly, minimizing downtime and enhancing surgical efficiency.

2. Ensuring Precision

Accurate calibration and alignment guarantee the precision required for complex surgical procedures.

3. Compliance with Standards

Meeting regulatory and safety standards during installation protects patients and healthcare providers.

4. Training and Familiarization

The installation process includes essential training for surgeons and staff, ensuring they can operate the system effectively.

5. Reducing Long-Term Costs

A seamless installation reduces the likelihood of technical issues, minimizing maintenance expenses and maximizing return on investment.

Key Steps in Da Vinci System Installation

Installing the Da Vinci Surgical System involves several key steps, each tailored to ensure optimal performance and integration into the healthcare facility.

1. Pre-Installation Assessment

- Facility Evaluation: Analyze the operating room layout to determine the best placement for the system.

- Infrastructure Review: Ensure the facility meets technical requirements, including power supply, network connectivity, and space dimensions.

- Workflow Analysis: Assess the surgical team’s workflow to integrate the system seamlessly into existing processes.

2. Delivery and Assembly

- Delivery Coordination: Work with the manufacturer to schedule and manage the safe delivery of the system.

- Component Inspection: Verify that all system components are intact and meet quality standards.

- Physical Assembly: Assemble the robotic arms, vision cart, and surgeon console with precision.

3. System Configuration

- Software Installation: Load and configure the latest software to ensure compatibility and optimal functionality.

- Calibration: Align the robotic arms, instruments, and cameras for precise operation.

- Connectivity Setup: Establish network connections for data integration and remote monitoring.

4. Testing and Quality Assurance

- System Testing: Conduct comprehensive tests to verify system functionality, including movement accuracy and visualization clarity.

- Simulated Procedures: Perform trial runs to ensure the system is ready for actual surgical use.

- Regulatory Compliance: Validate that the installation adheres to safety and regulatory standards.

5. Training and Orientation

- Surgeon Training: Provide hands-on training for surgeons to familiarize them with the system’s controls and capabilities.

- Staff Education: Train operating room staff on system setup, instrument handling, and troubleshooting.

- Ongoing Support: Schedule follow-up sessions for advanced training and system updates.

Considerations for a Seamless Installation

Achieving a seamless installation requires careful attention to several factors:

1. Choosing the Right Installation Team

Work with certified installation experts provided by the system manufacturer to ensure adherence to best practices and technical specifications.

2. Optimizing Operating Room Design

Plan the operating room layout to accommodate the system’s components while ensuring sufficient space for surgeons and staff to work efficiently.

3. Ensuring Compatibility

Verify that the system is compatible with existing surgical equipment and hospital infrastructure.

4. Scheduling Installation

Coordinate installation at a time that minimizes disruption to the facility’s operations.

5. Budget Planning

Account for all costs associated with installation, including staff training, infrastructure upgrades, and potential downtime.

Benefits of a Seamless Da Vinci System Installation

A properly installed Da Vinci Surgical System offers numerous advantages that elevate surgical practices:

1. Enhanced Surgical Precision

Accurate installation ensures the system delivers precise movements, reducing the risk of errors and improving patient outcomes.

2. Improved Workflow Efficiency

Integrating the system seamlessly into the operating room streamlines workflows, allowing for faster and more efficient procedures.

3. Increased Surgeon Confidence

Comprehensive training and proper setup empower surgeons to perform complex procedures with greater confidence and control.

4. Reduced Maintenance Costs

Correct initial installation minimizes technical issues, lowering long-term maintenance expenses.

5. Patient Safety

Meeting regulatory standards during installation ensures a safe surgical environment, reducing the risk of complications.

6. Enhanced Hospital Reputation

Offering cutting-edge robotic surgeries positions healthcare facilities as leaders in advanced medical care, attracting more patients.

Challenges in Da Vinci System Installation

While the installation process is highly structured, it can present challenges that require proactive solutions:

1. Space Constraints

Limited operating room space may require modifications to accommodate the system’s components.

2. Technical Requirements

Ensuring compatibility with existing infrastructure, such as power supply and data networks, can be complex.

3. Training Needs

Comprehensive training for all staff members takes time but is essential for successful system integration.

4. Initial Costs

The high upfront cost of the system and installation can strain hospital budgets.

5. Minimizing Disruption

Installing the system without disrupting ongoing surgical operations requires careful scheduling and coordination.

Best Practices for Successful Installation

To overcome challenges and ensure a smooth installation, healthcare facilities should follow these best practices:

1. Collaborate with Experts

Work closely with the system manufacturer and certified installation teams for professional guidance.

2. Plan Ahead

Conduct detailed pre-installation assessments and create a comprehensive installation plan.

3. Engage All Stakeholders

Involve surgeons, operating room staff, and hospital administrators in the planning and training process.

4. Invest in Training

Prioritize thorough training programs to ensure all users are confident and proficient in operating the system.

5. Schedule Regular Maintenance

Plan for ongoing maintenance and software updates to keep the system running at peak performance.

Conclusion

Installing the Da Vinci Surgical System is a significant step toward revolutionizing surgical care, offering unmatched precision and improved patient outcomes. A seamless installation process ensures the system operates efficiently, integrates smoothly into existing workflows, and meets the highest standards of safety and performance. By partnering with experts, investing in comprehensive training, and prioritizing careful planning, healthcare facilities can unlock the full potential of this groundbreaking technology. The investment in a seamless installation not only benefits surgeons and staff but also establishes the facility as a leader in advanced, patient-centered care.